Advantages and disadvantages of broaching

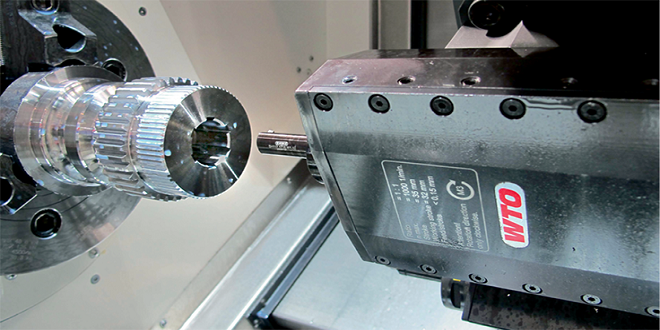

Broaching, a method of metalworking involves the use of a toothed tool called a broach to remove material from a piece. Broaching can be done in two ways: rotary or linear. Let’s take a look at each. Let’s take a look at each step. Linear broaching is the preferred method, since it is the most commonly used. Although less common, rotary broaching can still be done successfully.

Broaching has a primary advantage: It is extremely accurate. It has a tolerance of 0.0075mm and is suitable for mass production. It can also be used for internal and external surface finishing. broaches uses cutting fluid. This allows for high precision and very tight tolerances. This technique has a disadvantage. It cuts only through surfaces. Defects in the final product can cause problems. It is difficult to restore a damaged broach.

Broaching has another advantage: It is fast. Broaching a typical piece of work takes six to thirty seconds. Larger pieces can be completed in between 30 and 90 seconds. Broaching is a faster process than any other cutting method, making it an ideal choice for mass production. Because the tool and operator were designed for mass production, the final product is usually dimensionally stable. To increase tool life, broaching tools can be coated with titanium Nitride.

Internal shaping is the most popular type of broaching. A keyseat is the most common type of internal shape that can easily be broached. To prevent rotation, keyseats are grooves that are placed axially within a shaft. An arbor press is used to push the broaching keyseats through the workpiece. This assures precision. This is also true for keyhole broaching. A different machining process is required if an external shape needs to be created.

Broaching is an old method of metalworking. It’s an important part of industrial operations. Broaching is a common tool used by manufacturers in the aerospace and automobile industries. It allows them to make high-quality, precise parts. Broaching is a continuous tool that can only be used to create multiple angles and contours at once. Broaching is not recommended for thin walls or delicate cross sections. Broaching is not suitable for very thin walls or delicate cross sections.

There are basic preventative steps that can be taken depending on the size of your boat. Here’s how to prevent broaching if you are unsure. Use a backstay when you are sailing downwind. Although it may not seem like much at first, it is enough to stop a boat depowering its mainsail and heeling. Colgate suggests that you consult the manual or look out for signs of trouble if you are unsure.

For large-scale production, horizontal broaching machines work best. There are two types of vertical broaching machines available: push-down and pull-up. Most people use the pull-up model. You can either drive them with hydraulics or by electro-mechanical drives. This is the most economical option. Make sure you choose the right vertical broaching machine for your job. A hydraulic drive will allow for smooth cutting. Somma Tool offers affordable broached products.

Each type of broaching machine has a different purpose. The first three rows are generally chip breakers. The last few rows are also called finishing teeth. Some broaches combine semi-finishing and cutting teeth. The former can be used for many materials but a square broach works best for creating and expanding irregular shapes. The last type of broaching machine is a follower end. It supports the tool’s components.

Horizontal broaching machines can be either vertical or horizontal. Horizontal machines are easier than vertical ones. Horizontal machines include a support frame, drive, and holding fixture. Vertical machines use multiple rams and are more complex. Horizontal machines can be used internally, but vertical machines are better suited to external machining. The horizontal machine is generally easier to maintain and requires less training. However, vertical broaching machines have some benefits.

Vertical machines use a hydraulic system for the drive. It is capable of handling large workpieces as well as long broaches. Both vertical machines can perform multiple tasks. A starting hole is required if you want to broach an interior piece. You can use either a vertical or horizontal broaching machine depending on how complex your workpiece is. This is the most popular option and accounts for nearly one-tenth all broaching machines currently in use.

Naa Songs is a popular online platform for downloading and streaming music from various genres. It offers a wide range of songs in an easy-to-use interface, providing users with a seamless music-listening experience.